Simulated Moving Bed Chromatography

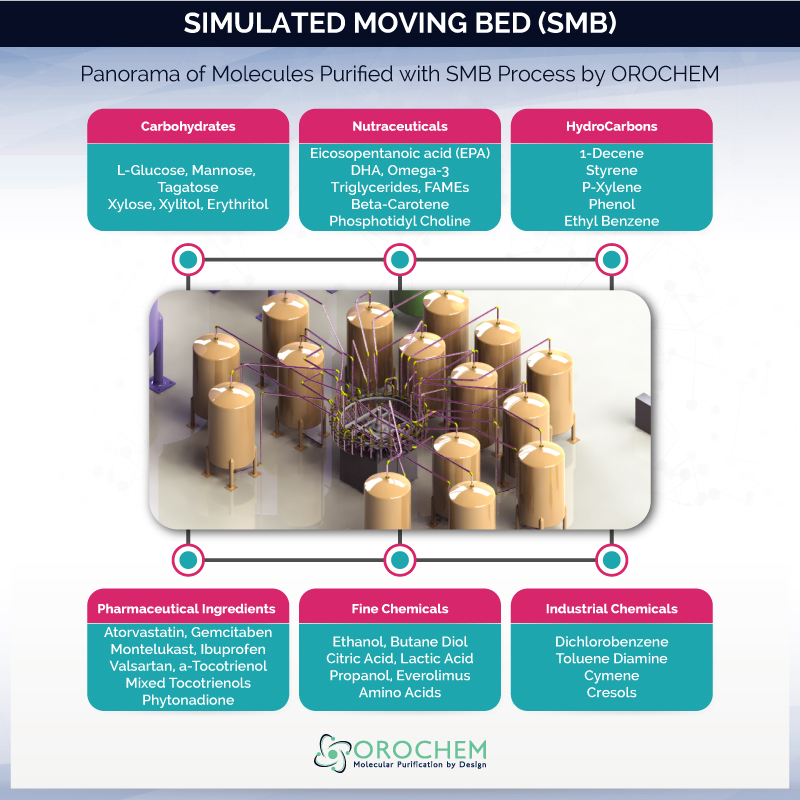

Established in 1996, Orochem is globally recognized as a unique vertically-integrated organization for commercial ton-scale purification of economically viable molecules using Simulated Moving Bed Chromatography. Orochem conducts proof of concept leading to pilot scale purification to validate feasibility and viability of commercial scale-up using proprietary chromatographic/ion exchange separation technique involving simulated moving bed (SMB) technology. To date, Orochem has successfully installed pilot scale and commercial scale purification systems at customer’s sites in north America, Europe and Asia, such as protein purification SMB systems of plant proteins, recombinant proteins, and whey proteins; nutraceutical and API purification SMB systems of phospholipids, Omega 3 fatty acids, curcuminoids, and sugars. In addition, Orochem successfully manufactures up to kilo scale purification products of chiral drugs, beta-carotene, tocotrienols , 2,3-butanediol, 1-decene, and anthocyanin.

SMB (Simulated Moving Bed) Background:

Simulated moving bed (SMB) technology is a chromatography technique that is traditionally used in oil and energy industry for recovery and purification of p-xylene and other aromatic components separated from naphtha feed. After it became commercialized heavily into the oil industry, SMB technology made its mark on the food industry by separating fructose from glucose in a molasses feed. Since then (1990s), SMB chromatography has become increasingly popular with biotechnology companies for purification and recovery of active pharmaceutical intermediates (APIs). Several examples of processes established in industry include the SORBEX® process as well as the PAREX®, and Aromax® for recovery of p-xylene from C-8 isomer mixtures both commercialized by UOP. Other examples of SMB processes commercialized (also from UOP) include Ebex® for the separation of ethylbenzene from a mixture of C-8 aromatic isomers, Molex® for the separation of n-parafin’s from branched and cyclic hydrocarbons, and Olex® for the separation of olefins from parafins. Other examples in the chemical industry are Cresex® and Cymex® for the separation of p-cresol and p-cymene from its isomers and Sarex®.

To understand and utilize the SMB technology, it is imperative to study techniques of batch or column chromatography. All research and development efforts to operate an SMB are focused on column chromatography studies. Once components in a material are able to be separated at reasonable capacity with respect to a certain mobile phase, stationary phase, and feed flow rate, a scale up to SMB is possible. Column chromatography, at any scale, is not practical to use for large scale production and purification of molecules. Compared to SMB technology, in column chromatography, the stationary phase is not utilized efficiently. This is because the separation zone between the components decreases during a column chromatography separation. In an SMB, the separation zone is large and is maintained at a constant width. Also, compounds are often unable to be separated in column chromatography because the column length is usually not long enough. Overall, in column chromatography, the stationary phase is largely under-utilized and thus most column separation processes require excess amounts of solvent to complete a separation between compounds. One of the major drawbacks of column chromatography is that it is a batch or linear process which results in the process having to be repeated to achieve a similar result as continuous SMB process. Thus, a column chromatography separation is always expensive to scale up as compared to an SMB.

Work model and Capabilities:

- Work model supports the process from discovery phase to lab scale and all the way to production scale

- Orochem has capabilities of manufacturing customized adsorbents which can efficiently work on SMB process.

- Orochem has a team of highly experienced people in the field of SMB – We have a team of chemists, Chemical and Mechanical Engineers working closely right from the discovery stage to the production stage

Cost Effectivness :

- Orochem SMB large scale models are based on 300um and larger particle size thereby reducing the cost of the adsorbent and equipment.

Support and services:

- Orochem provides full support for further process development and optimization even after installation of the process

- Orochem provides full documentation and technical services required for cGMP applications

- Orochem deligently works towards making the product most cost effective in the industry

- Orochem has in house analytical equipment's like HPLC, GC, mass spec, FTIR, UHPLC etc.

- Application Note

- Flyer / Documents

Not available!

SIMULATED MOVING BED CHROMATOGRAPHY